产品概述 Product Overview

辅材制件(复材制件)包含5种不同类型的复合材料制件,通过先进的复合材料技术,在性能上可替代传统金属机加工件,实现减重、耐腐蚀等效果,适用于汽车、航空航天、医疗器械等多个高端制造领域。 Composite components include 5 different types of composite material parts. Through advanced composite technology, they can replace traditional metal machined parts in performance, achieving weight reduction, corrosion resistance and other effects, suitable for automotive, aerospace, medical devices and other high-end manufacturing fields.

薄壁复材件 Thin-Wall Composites

具有薄壁结构,重量轻、强度高,适用于对重量和空间有严格要求的场景。 With thin-wall structure, lightweight and high strength, suitable for scenarios with strict weight and space requirements.

复杂功能结构件 Complex Functional Structures

结构复杂且集成多种功能,可满足特定工况下的多维度需求。 Complex structure integrating multiple functions, meeting multi-dimensional requirements under specific conditions.

低成本大批产件 Low-Cost Mass Production

采用优化工艺实现低成本、大批量生产,兼顾性价比与基本性能。 Using optimized processes for low-cost, large-scale production, balancing cost-effectiveness with basic performance.

薄壁异性件 Thin-Wall Irregular Parts

薄壁且形状不规则,适应特殊安装空间与结构要求。 Thin-wall and irregular shaped, adapting to special installation space and structural requirements.

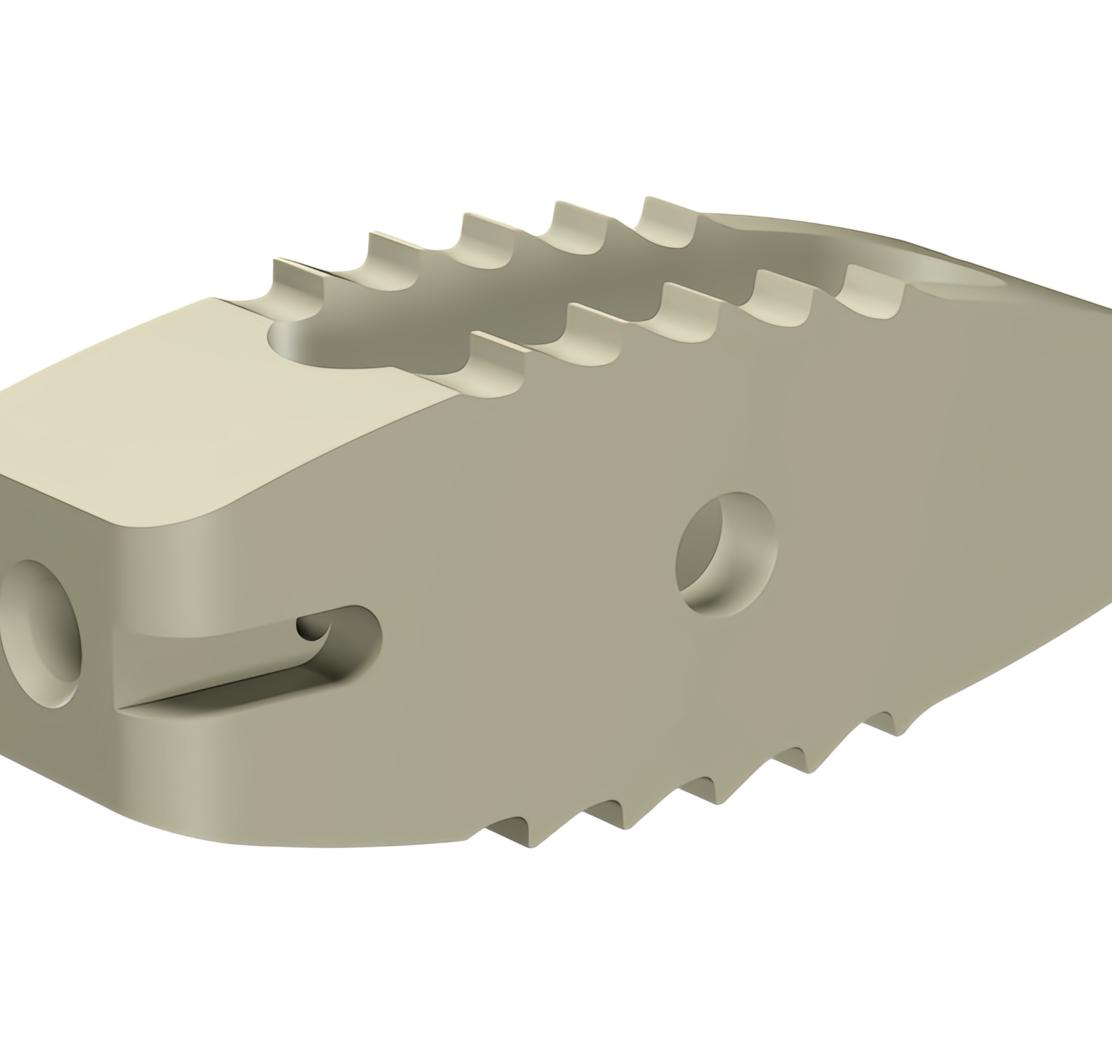

金属机加替代件 Metal Machining Replacements

在性能上可替代传统金属机加工件,实现减重、耐腐蚀等效果。 Can replace traditional metal machined parts in performance, achieving weight reduction and corrosion resistance.

产品展示 Product Gallery

行业应用案例 Industry Application Cases

航空航天:轻量化与性能突破 Aerospace: Lightweighting & Performance Breakthrough

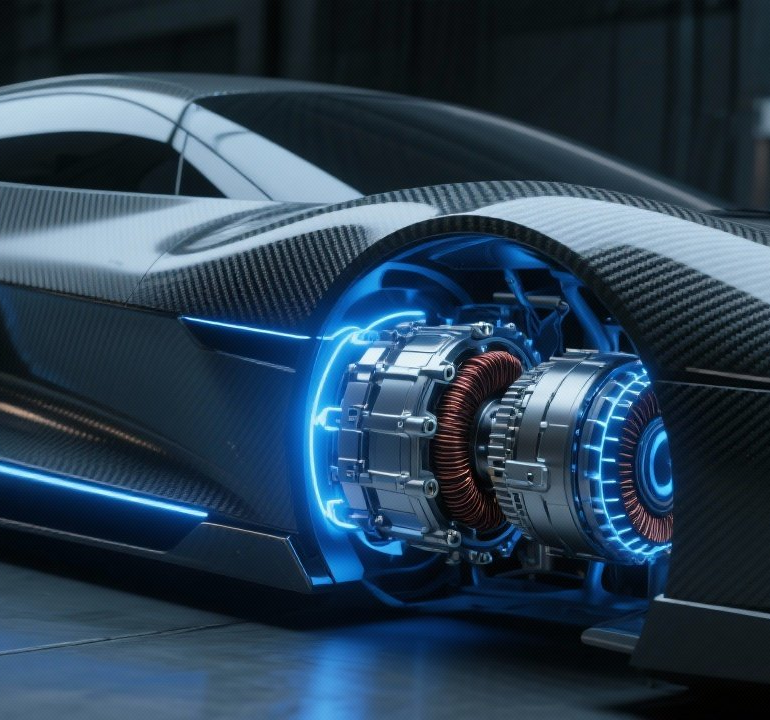

汽车工业:碳纤维车身与电驱革新 Automotive: Carbon Fiber Body & Electric Drive Innovation

建筑行业:绿色模板技术 Construction: Green Template Technology

医疗领域:生物相容性与精准植入 Medical: Biocompatibility & Precision Implantation

产品特性 Product Features

轻量化设计 Lightweight Design

相比传统金属材料,可实现30%-50%的减重效果,提升整体性能。 Compared to traditional metal materials, achieving 30%-50% weight reduction for improved overall performance.

高强度性能 High Strength Performance

优异的力学性能,在减重的同时保持或提升结构强度。 Excellent mechanical properties, maintaining or improving structural strength while reducing weight.

耐腐蚀性 Corrosion Resistance

优异的化学稳定性和耐腐蚀性能,适用于恶劣环境应用。 Excellent chemical stability and corrosion resistance, suitable for harsh environment applications.

定制化设计 Customized Design

可根据特殊形状和性能要求进行定制化设计和制造。 Customizable design and manufacturing according to special shape and performance requirements.

环保可持续 Environmentally Sustainable

材料可回收利用,符合绿色制造和可持续发展要求。 Materials are recyclable, meeting green manufacturing and sustainable development requirements.

成本优化 Cost Optimization

通过工艺优化和规模化生产,实现成本控制和性价比提升。 Achieving cost control and cost-effectiveness improvement through process optimization and scale production.

应用领域 Applications

辅材制件广泛应用于多个高端制造领域,为各行业提供材料升级和性能优化解决方案。 Composite components are widely used in multiple high-end manufacturing fields, providing material upgrade and performance optimization solutions for various industries.

航空航天 Aerospace

飞机机翼、卫星结构、火箭整流罩等关键部件的轻量化制造。 Lightweight manufacturing of critical components such as aircraft wings, satellite structures, and rocket fairings.

汽车工业 Automotive

车身面板、电池外壳、内饰件等部件的轻量化和性能提升。 Lightweighting and performance improvement of body panels, battery housings, interior components.

医疗器械 Medical Devices

假肢、椎间融合器、手术器械等医疗设备的生物相容性部件。 Biocompatible components for medical devices such as prosthetics, intervertebral fusion cages, surgical instruments.

建筑工程 Construction Engineering

建筑模板、结构加固件、装饰面板等绿色建筑材料。 Green building materials such as construction templates, structural reinforcement components, decorative panels.

体育用品 Sports Equipment

自行车车架、网球拍、高尔夫球杆等高端体育器材。 High-end sports equipment such as bicycle frames, tennis rackets, golf clubs.

国防军工 Defense & Military

防弹装甲、雷达罩、导弹部件等军用装备的防护和结构件。 Protective and structural components for military equipment such as bulletproof armor, radar radomes, missile components.

质量保证 Quality Assurance

先进制造工艺 Advanced Manufacturing Process

采用先进的复合材料成型工艺,确保产品尺寸精度和性能一致性。 Using advanced composite molding processes to ensure product dimensional accuracy and performance consistency.

严格质量标准 Strict Quality Standards

严格按照航空航天、汽车、医疗等行业标准进行生产和检测。 Strictly produced and tested according to aerospace, automotive, medical and other industry standards.