产品概述 Product Overview

真空辅材类产品专门为真空导入工艺设计,包含19种不同功能的辅助材料,涵盖导流、抽气、控制、检测等各个环节,为风电叶片、游艇、复合材料制造提供完整的工艺解决方案。 Vacuum auxiliary materials are specially designed for vacuum infusion processes, including 19 different functional auxiliary materials covering flow control, vacuum extraction, control, and detection, providing complete process solutions for wind turbine blades, yachts, and composite material manufacturing.

产品展示 Product Gallery

核心产品 Core Products

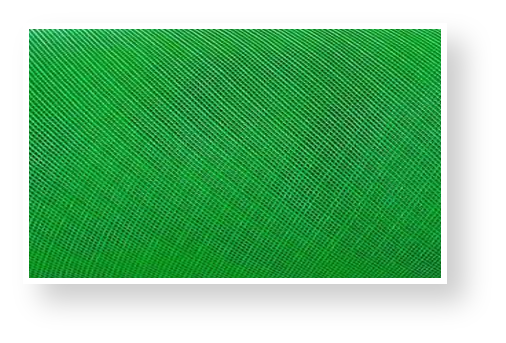

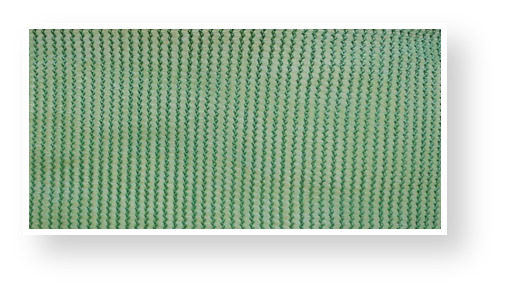

编织导流网 Woven Flow Media

适用于真空导入工艺,在真空导入成型中起到树脂导流作用。耐温高达140度,克重、幅宽可根据客户要求加工。 Suitable for vacuum infusion processes, providing resin flow in vacuum infusion molding. Temperature resistant up to 140°C, weight and width customizable.

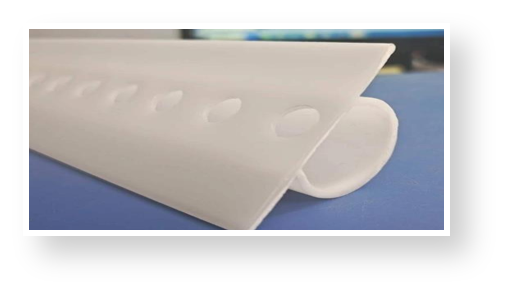

一体欧姆管 Integral Omega Tubes

由聚乙烯、聚丙烯加工挤出而成型,拥有良好的稳定性、耐高温性、耐老化性、防压痕,适用于风电叶片及其他真空导注工艺。 Formed by polyethylene and polypropylene extrusion processing, with good stability, high temperature resistance, aging resistance, and pressure mark prevention, suitable for wind turbine blades and other vacuum infusion processes.

核心产品技术规格 Core Product Technical Specifications

编织导流网技术参数 Woven Flow Media Technical Parameters

| 技术参数 Technical Parameter | 规格值 Specification |

|---|---|

| 材料 Material | 聚乙烯/聚丙烯 Polyethylene/Polypropylene |

| 结构 Structure | 多层立体编织;纵列3列,横列13列 Multi-layer 3D weaving; 3 vertical, 13 horizontal |

| 克重 Weight | 120g、160g、200g、230g(可定制) |

| 颜色 Color | 黑色、绿色 Black, Green |

| 最高使用温度 Max Working Temperature | 120°C |

| 渗透率 Permeability | 100% |

一体欧姆管技术参数 Integral Omega Tube Technical Parameters

| 技术参数 Technical Parameter | 规格值 Specification |

|---|---|

| 材料 Material | 聚乙烯、聚丙烯 Polyethylene, Polypropylene |

| 最高使用温度 Max Working Temperature | 140°C |

| 直径 Diameter | 内径16mm外径19mm、内径19mm外径22mm、内径25mm外径29mm |

| 颜色 Color | 半透明色(可定制) Translucent (Customizable) |

| 长度 Length | 4米(可定制) 4m (Customizable) |

| 耐压性 Pressure Resistance | 常温下正压20bar、负压1bar Positive pressure 20bar, negative pressure 1bar at room temperature |

完整产品系列 Complete Product Series

我们提供19种不同功能的真空辅助材料,满足各种复杂工艺需求 We provide 19 different functional vacuum auxiliary materials to meet various complex process requirements

编织导流网 Woven Flow Media

真空导入工艺树脂导流 Resin flow for vacuum infusion

拉挤楔型条 Pultruded Wedge Strips

菱形挤出导流介质 Diamond extruded flow medium

一体欧姆管 Integral Omega Tubes

稳定性好、耐高温 Good stability, high temperature resistance

VAP膜抽气袋 VAP Film Vacuum Bags

无压痕灌注产品 Mark-free infusion products

复合导流网 Composite Flow Media

增加工作效率 Increased work efficiency

挤出导流网 Extruded Flow Media

树脂导流功能 Resin flow function

真空管 Vacuum Tubes

抽油管和注胶管 Oil suction and resin injection tubes

欧姆管(常规) Omega Tubes (Standard)

良好稳定性和耐高温性 Good stability and high temperature resistance

螺旋管 Spiral Tubes

挤压成型工艺 Extrusion molding process

连续毡 Continuous Mat

无碱玻璃纤维长丝 E-glass fiber filament

防压痕板 Anti-Mark Plates

与欧姆管配套使用 Used with omega tubes

耐高温钢丝管 High-Temp Steel Wire Tubes

140°C高温应用 140°C high temperature applications

注胶阀门 Resin Injection Valves

二通、三通、四通、五通 2-way, 3-way, 4-way, 5-way

VAP膜-单向透气膜 VAP Film - One-Way Breathable

阻挡树脂允许气体通过 Blocks resin, allows gas passage

隔离膜 Release Films

有孔和无孔两类 Perforated and non-perforated types

透气毡 Breathable Felt

优良透气性和贴合性 Excellent breathability and conformability

T型注胶板 T-Type Injection Plates

风电行业真空导注 Wind industry vacuum infusion

螺栓保护套 Bolt Protective Sleeves

防氧化、防UV紫外线 Anti-oxidation, UV protection

脱模布 Release Fabrics

高强度聚酯脱模布 High-strength polyester release fabric

应用领域 Applications

真空辅材类产品广泛应用于各种真空导入成型工艺,为复合材料制造提供专业支持。 Vacuum auxiliary materials are widely used in various vacuum infusion molding processes, providing professional support for composite material manufacturing.

风电叶片制造 Wind Turbine Blade Manufacturing

为风电叶片的真空导注成型提供完整的辅助材料解决方案。 Providing complete auxiliary material solutions for vacuum infusion molding of wind turbine blades.

游艇制造 Yacht Manufacturing

支持游艇船体和各种船舶复合材料部件的真空成型工艺。 Supporting vacuum molding processes for yacht hulls and various marine composite components.

汽车配件制造 Automotive Parts Manufacturing

用于汽车复合材料部件的真空导入成型和灌注工艺。 Used for vacuum infusion molding and infusion processes of automotive composite components.

航空航天 Aerospace

为航空航天复合材料结构件制造提供高标准辅助材料。 Providing high-standard auxiliary materials for aerospace composite structural component manufacturing.

工业设备 Industrial Equipment

支持各种工业设备复合材料部件的真空成型制造。 Supporting vacuum molding manufacturing of composite components for various industrial equipment.

体育用品 Sports Equipment

制造高端体育器材和运动装备的复合材料部件。 Manufacturing composite components for high-end sports equipment and athletic gear.

质量保证 Quality Assurance

工艺专业化 Process Specialization

针对不同真空导入工艺环节,提供专业化的辅助材料解决方案。 Providing specialized auxiliary material solutions for different vacuum infusion process stages.

性能验证 Performance Verification

所有产品经过严格的性能测试,确保在实际工艺中的可靠性和稳定性。 All products undergo rigorous performance testing to ensure reliability and stability in actual processes.